UNIT SYSTEMS

Products

Industrial air treatment systems

▪ Patented aluminium modular system for construction of framing structure easy to assemble, suitable for AHU, painting, soundproof isolation, drying plants, storage, food ovens, shelter for electric equipments.

▪ Material used: aluminium profile in alloy 6060, corner post and omega profiles with single flange or double wall available also for Thermal Break system, die-casted aluminim accessories, PA6 Nylon, polypropilene, polyethylene, policarbonate, PVC, Epdm, Stainless steel and galvanized steel.

▪ Products: aluminium profiles, corners, omega joints, mounting feet, handles, locks, hinges, portholes, panel stops, gaskets, filter holder profiles, panels, louvers, dampers, mist eliminators.

▪ Finishings: painting, anodic oxidation, sandblasting, galvanization.

▪ Industrial design and use of highly advanced materials.

▪ A wide range of standard and customized profiles and accessories.

+ INFO

Products for photovoltaic systems

▪ System composed of aluminium profiles and accessories made of different materials, a wide range of shapes and dimensions for the assembling of a variety of photovoltaic systems on: flat roofs, corrugated roofs, industrial or civil roofs, installations on groud, shelters etc.

This systems is also used to build shelters for inverter and storage, modular switchboards.

▪ Material used: aluminium profiles, aluminium die-casted accessories. galvanised steel, stainless steel, PA6 nylon reinforced with fibreglass and others.

▪ Products: aluminium and stainless steel profiles, panel stops, special screws for roofs, square steel plates, spring sliders, triangles.

▪ Features: easy and fast assembling even carried out with simple tools directly at the construction site.

▪ Standard and customised profiles and accessories in order to meet the needs of customers.

+ INFO

Production

Aluminium profile extrusion

▪ Fully automatically production processes.

▪ Production capacity: 20.000 tons/year.

▪ Profile range: from 30 gr/mt up to 33 kg/mt.

▪ Alloy extruded: 6060, 6005, 6463, 6082, 6063, 1050.

▪ Presses: from 1800 tons up to 4000 tons.

▪ Customised extrusion.

▪ Available finishings: oxidation, painting, sandblasting.

▪ Mechanical machining on aluminium profile: cutting, drilling, shearing, milling.

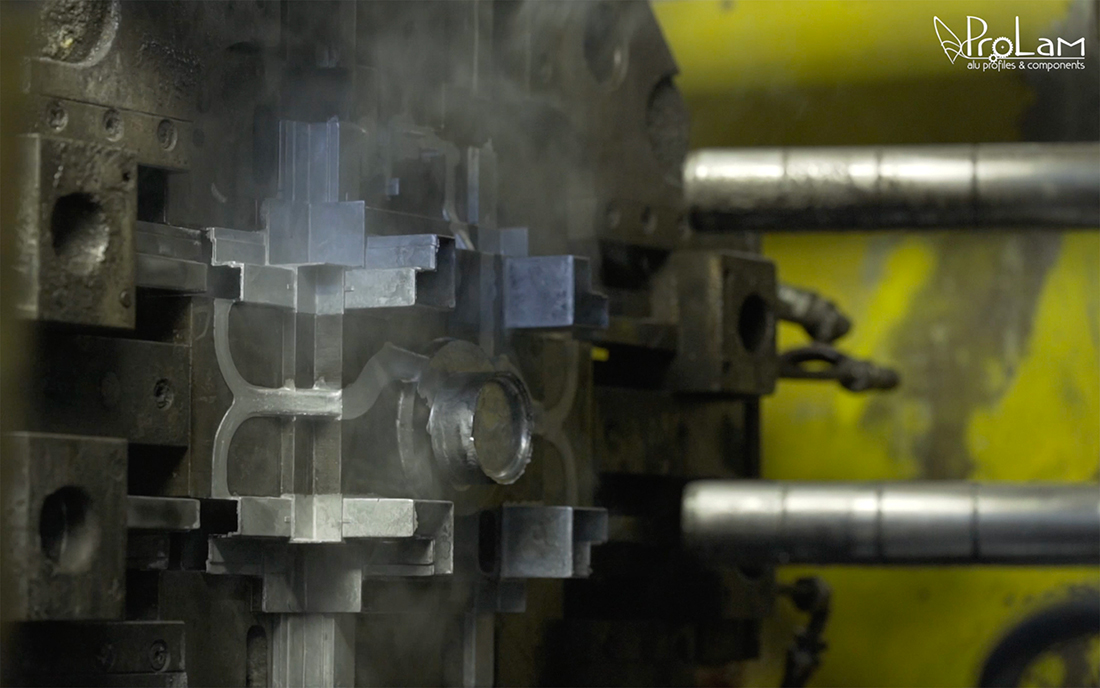

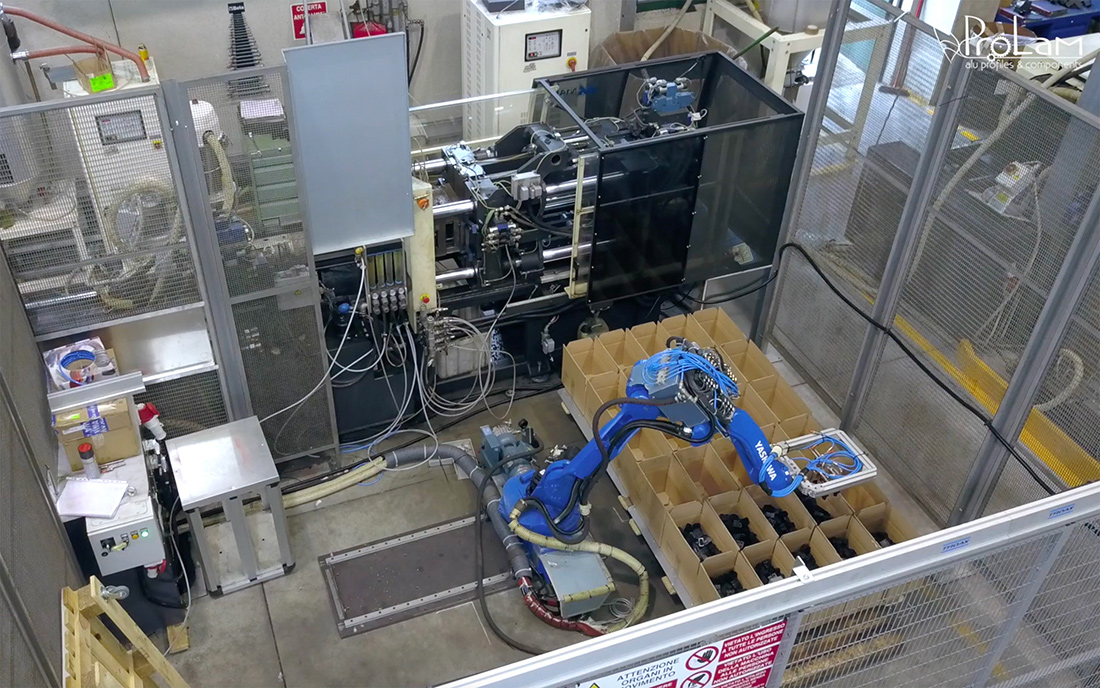

Aluminum alloy die-casting

▪ Presses of different power (from 300 to 800 tons) and a low energy consumption.

▪ Fully automated work stations with (the aid of) anthropomorphic robots and automatic management systems and shearing.

▪ Production of a vast array of article of different weight and volume.

▪ Finishing of die-casted articles: sandblasting or painting.

▪ Aluminium alloys: EN-AB 46100 and other.

▪ Mechanical machining: drilling, cutting, milling, thread.

Plastic material moulding

▪ Plastic injection moulding carried out by presses of different power (from 140 to 450 tons).

▪ Fully automated workstations with (the aid of) anthropomorphic robots and automatic management systems.

▪ Wide range of article on our stock.

▪ Materials: Pa 6 nylon reinforced with fibreglass or PP, policarbonate, etc.

▪ Highly qualitative and productive performances.

Warehouse

▪ Near Milan, the 7000 square/metre warehouse guarantees the availability of Aluminium profiles, accessories, Aluminium coils and sheets.

▪ Aluminium profiles (6 metre length) and coils are handled and loaded/unloaded from trucks with cranes.

▪ Fork lifts are used to handle other goods packed on pallets.

▪ Delivery is usually made within 2 - 3 days from the approval of order’s confirmation, directly with our own trucks or through established international shipping agents.

Engineering

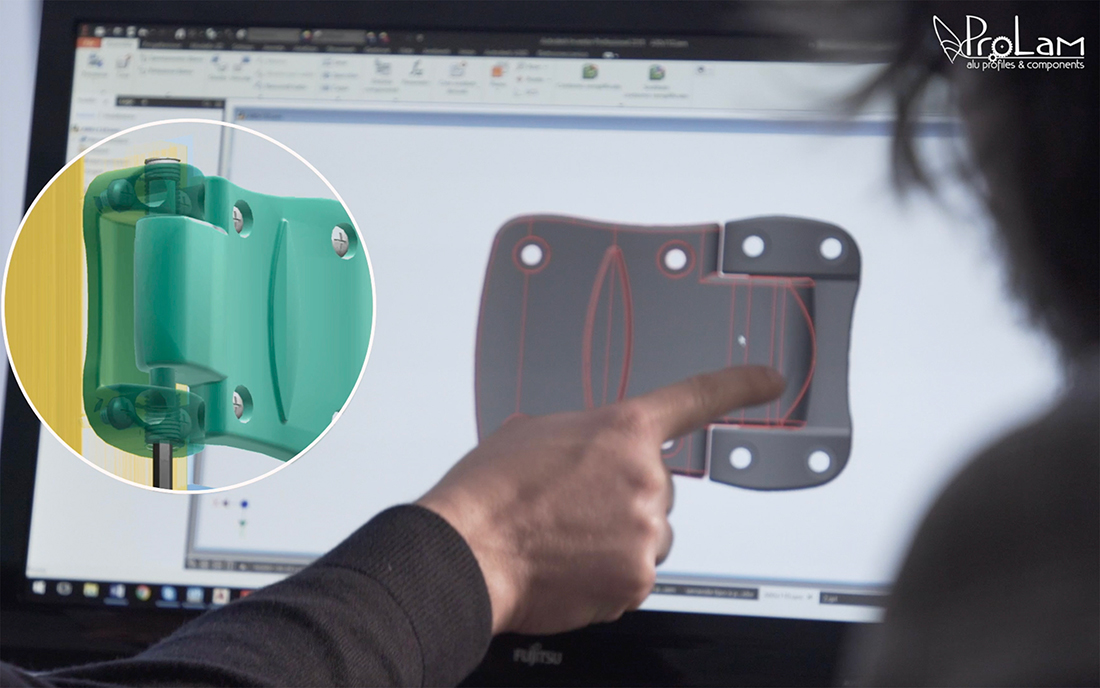

Mechanic component design

▪ Research and development: the innovation and a constant research are Prolam's strenght.

▪ Technical Department: the Customer is followed step by step by professional team to develop an idea into a real project.

▪ Applications: the Technical department makes use of latest generation solid modeling softwares.

▪ Test: our products undergo a different and strictly quality and resistance tests.

▪ Certifications are issued by well-known National and international Certification Bodies.

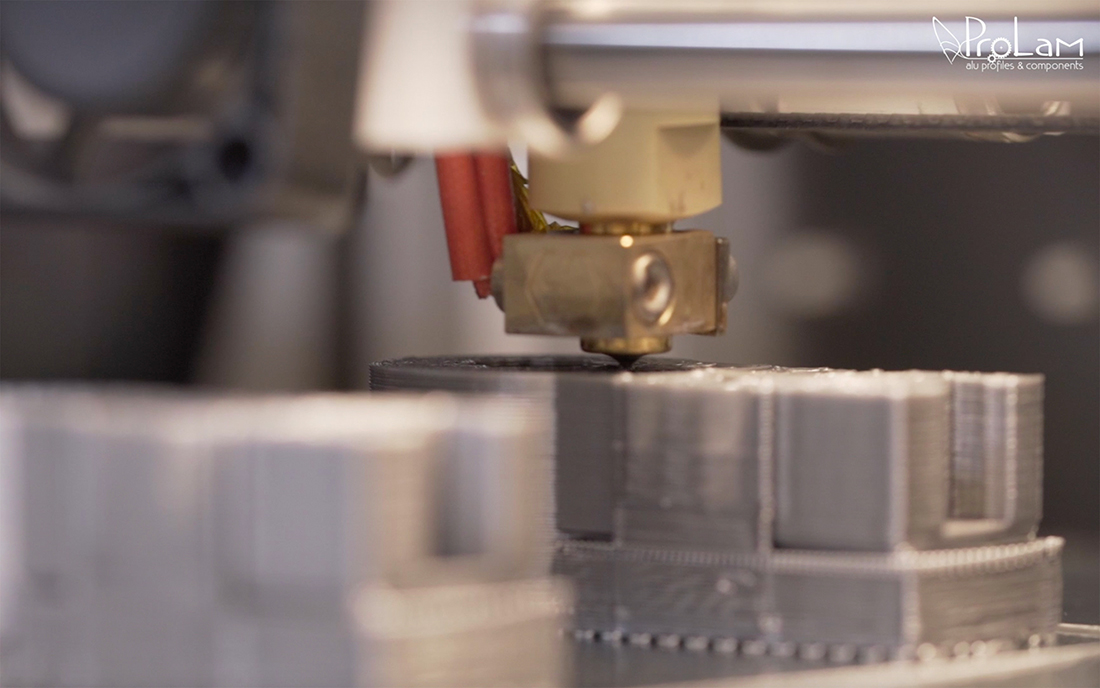

Rapid prototyping 3D

▪ Prototype construction made of different material using 3d printers.

▪ Prototype costruction of several dimensions, weights and colours.

UNIT SYSTEMS

CABINET AND STORAGE

FRAME SYSTEM

ALUMINIUM DIE CASTING

PLASTIC MOULDING

ENGINEERING

CONTACT US

Fill out the form to request more information. One of our managers will contact you as soon as possible.